When equipment of any type is intended to be used in a potentially hazardous area, the equipment must be designed, tested, labeled, and approved for use according to the classification of the point of installation. One of the main purposes of IECEx and ATEX zoning is to facilitate the proper selection of equipment to ensure safe working conditions. If a customer has a hazardous location and a non-approved or wrongly chosen instrument is installed, this instrument may create an ignition risk.

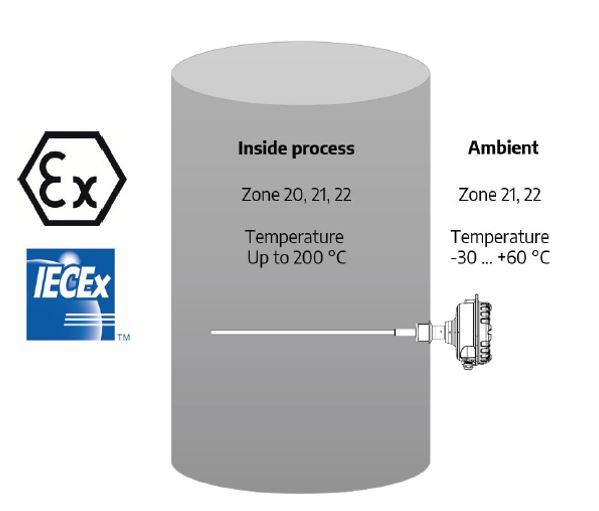

It is often the case that the inside of a process has continuous high levels of dust, and the outside of the duct rarely has high dust concentrations. In cases like this, there will be a greater demand for the instrument inside the duct vs outside.

Definitions of different Zones:

Zone 20

A place in which an explosive atmosphere in form of a cloud of combustible dust in the air is present continuously or for long periods or frequently for short periods. For example, a mill or pneumatic conveying system

Zone 21

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur occasionally in normal operation. For example, bagging point and inspection ports that are frequently opened.

Zone 22

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but if it does occur will persist for a short period of time only. For example, leaks or spillages.

IECEx/ATEX Zone approvals

The certified S303 Ex and S304 Ex models can be used in the following applications: