More safety

Less emissions

Optimum results

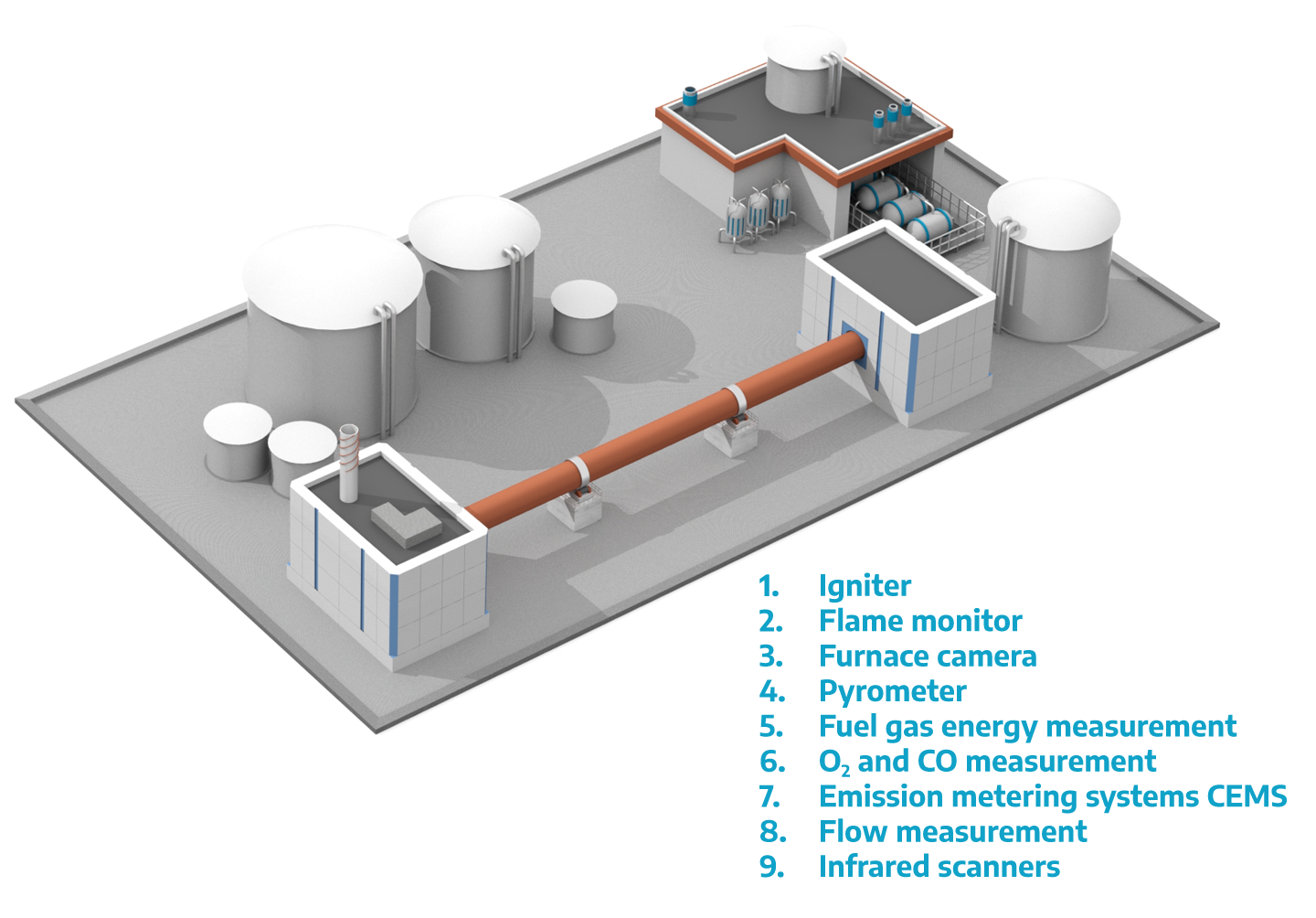

Lime kiln

Igniters (Combustion control)

The function of the igniter is to ignite the fuel of the burner. By choosing the right type of igniter Sintrol can significantly improve combustion gas ignition reliability, lime kiln safety and production efficiency. Continuous lighters operate as so-called as a pre-burner. Read more about igniters.

Flame monitors (Combustion monitoring)

The flame monitor ensures that the flame burns. If the flame monitor does not detect a flame, the fuel supply to the burner is stopped. If the fuel supply is not cut off, there is a risk of explosion if it re-ignites. The flame monitor is a safety device for the lime kiln and with our experience we can ensure that the safety and foresight associated with combustion is in order. Read more about flame monitors.

Thermal cameras (Combustion control)

With the furnace camera, you get a real-time image of the combustion and are thus able to monitor the fire event and find out the problems related to the combustion both visually and automatically. With our Vulcan 12C-2C camera you can monitor the following:

- Flame shape

- Lime sludge accumulation

- Lime falling into the cooler

- Grain size monitoring

- Furnace camera temperature measurement can monitor the temperature of critical objects and connect alarms to the automation system

Pyrometers (Combustion control)

The pyrometer measures the temperature of the burnt lime. Reliable and accurate lime temperature measurement controls the lime kiln burning process and the homogeneity of the quicklime. The temperature of the quicklime correlates with the residual carbonate in the mesa, which is important information for the operation of the process.

Fuel gas energy measurements (Combustion control)

Wobbe Index and Calorimetric values for constant kiln temperature management is in many cases an absolute must because the burner gas composition may vary greatly especially if the gas is produced in an on-site gasifier. At a constant flow rate the burner will produce a variable amount of heat depending on the burner gas calorific value. This may easily cause problems in controlling the kiln temperature and Sintrol solution to this problem is to equip the gas intake line with a calorimeter so that the gas flow rate can be adjusted for a uniform calorific value and uniform temperature.

O2 and CO measurement (Combustion monitoring)

O2 and CO measurement is an essential part of controlling the relationship between the combustion gas and the combustion air. The energy content of the flue gas may vary greatly, especially if it is produced in a gasifier located in the plant, in which case continuous information on the oxygen and carbon monoxide content of the flue gas is required for the control of the combustion air. There are also known risks associated with O2 and CO gases, such as deterioration of the fire caused by too high a concentration of carbon monoxide and explosions in electrostatic precipitators. Too much oxygen, in turn, can increase fuel consumption unnecessarily. We use a measurement solution suitable for very dusty and difficult conditions.

Continuous emission management systems CEMS

Measuring emissions and caring for the environment are important issues for all of us, due to the strict environmental requirements today. With its long experience, Sintrol can take care of the regularity and reliability of emission measurements. The emission measurements required by the authorities are made with continuous analyzer systems, which Sintrol is responsible for designing and building. Measurements ensure that TRS, NOx, CO, SO2, O2, particles are not exceeded, and production meets environmental requirements.

Flow measurements (Emissions measured with continuous analyzers)

In accordance with official requirements, emission measurements must be monitored continuously. These measurements ensure that nitrogen oxide emission limits are not exceeded and production meets environmental requirements. When measuring emissions, concentration values alone are not enough, and flow measurements can be used to make volume flows through the calculated actual emission values.

Infrared scanners (Kiln surface monitoring)

Infrared scanners measure the surface temperature of the kiln. The measurement ensures the condition of the brick lining as potential brick damages appear as hot spots on the temperature map generated by the scanner software. With this information, you can find the part to be repaired on time and the oven will last longer. The scanner also detects the formation of a ring in the oven. The rings stands out as dark and colder zones on the temperature map. Sintrol designs the locations and the required number of scanners with 3D modeling. Often, oven support structures create blind spots on line scanners that can be measured with the help of additional dot scanners.

When you want to optimize the operation of your lime or cement kiln but control risk and emissions, Sintrol can find the most suitable solution for your process. With the Sintrol Lime Kiln instrumentation solution, you can control the process from start to finish. We can provide a comprehensive solution or focus on specific process stages – according to your needs.

Together, we’ll determine your biggest process challenges. Then, our expert team will assess your situation and design a lime kiln measurement solution that meets your specific needs – including scanning, combustion monitoring and emission measurement.

We’ll find the best measuring and analyzing solutions from our wide product range, and be there to support you throughout the lifecycle of your Sintrol solution.

Our local service team will will be there for you throughout product installation and commissioning, and will ensure your staff is trained to use the equipment.

+ 358 9 5617 3625

+ 358 9 5617 3625